How to make Japanese sword / No.3

==> How to make a Japanese sword No.2

5.SU-NOBE(Forming the Blank)

After finishing ARA-NOBASHI, the composite steel bar is formed into the blank(SU-NOBE; rough shape of sword).

This process is called SU-NOBE.

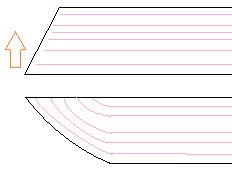

At first the front edge is cut off at a slant and BO-SHI(the cutting edge) is formed in the direction of the arrow.

The reason why BO-SHI is formed backword direction is that the layer folw of the steel should be brought together wiht the shape of BO-SHI.

The steel block is formed into the shape of the sword in the next stage, but the length of it is about 1 SUN(about 3cm) than final length, because the length of it grows while being formed with a hand-held hammer.

The section of SU-NOBE is rectangular, and we could know the finished width by gauging width and thickness of it.

6.HI-ZUKURI

Shaping the Blade

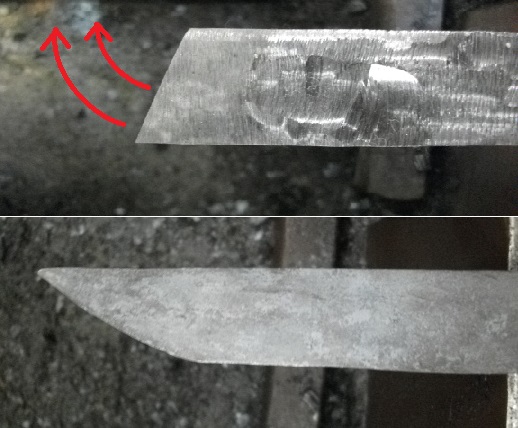

About 15cm section of the blank is each heated at a time in the forge, and it is hammered edge side and back side to form the shape that looks like a thin rhombus.

7.ARA-SHIAGE

The shape of the sword after HI-ZUKURI is very well defined with using a file and a SEN .

This is the case of TAN-TO.

==> How to make a Japanese sword No.4