How to make Japanese sword / No.2

==> How to make a Japanese sword No.1

3.ORIKAESHI-TANREN [ KAWA-GANE, SIN-GANE TOU ] (Forging with repeating the process of heating and hammering [ Jacket steel, Core steel etc ])

After assembling the steel block for forging, the block is heated and elongated to a rectangle shape, made a deep cleft at the centre of it and folded the rectangle back upon itself.

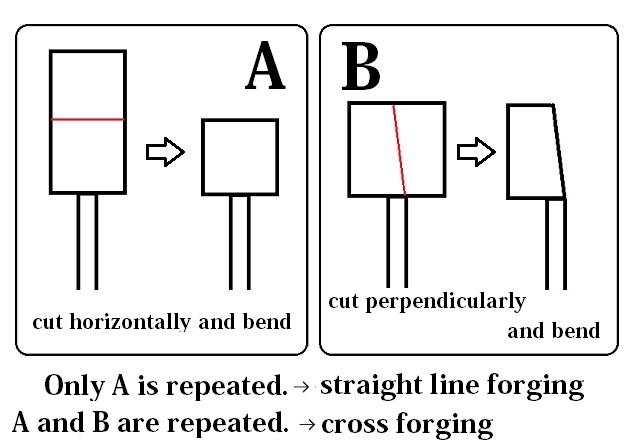

The steel is again heated for the forge welding, elongated, notched, and folded. This process is repeated. There are two ways of forging: straight line forging and cross forging. Which way to employ is decided as the occasion requires. The process is repeated about ten times for core steel and about fifteen times for jacket steel, but it is not strict rule. A number of folding times is decided on the strength of a proper viscosity and hardness, and condition of the steel surface in the end.

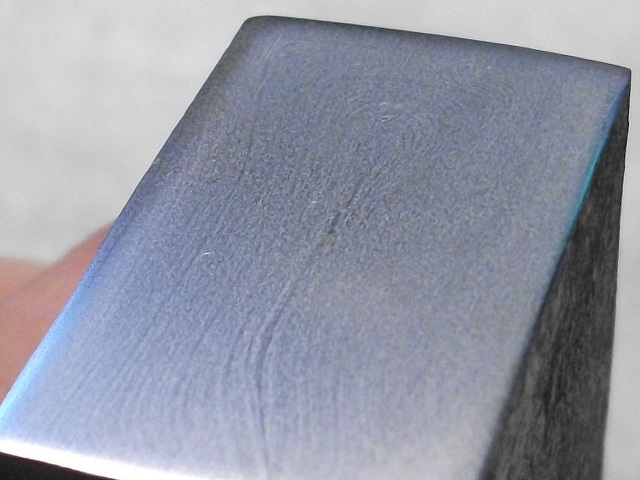

A steel surface is made as a result of forging. Fifteen times of forging makes layers of about 32,768 (gtwo to the power of fifteenh).

Because of these layers, the surface of the Japanese sword show specific beauty of the surface which is called HADA.

There is various shape of a ground pattern for HADA, mainly MASA-ME(straight grain), MOKU-ME, ITA-ME(cross grain), AYA-SUGI etc . In many cases there are several patterns coexist on the sword.

4.TSUKURI-KOMI (Forming the steel stock)

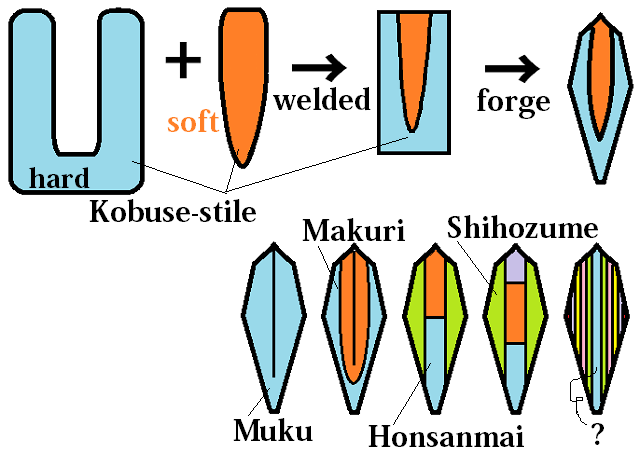

After prepared several different pieces of steel which have different viscosity and hardness, TSUKURI-KOMI process, which configures inner structure of a sword, is started.

A enlarged photo of a section of MUKU

Several steel bars with different property are forged welding and inner structure of the sword is constructed.

KOBUSE-KOTEI (Process of forming the steel stock)

The composite steel bar is elongated while heating to rough rod shape and formed into the blank that will become the sword.

> How to make a Japanese sword No.3